Glass bottle product testing is an important part of ensuring the quality of glass bottles.We have machine testing and manual testing to ensure that your product quality is qualified.

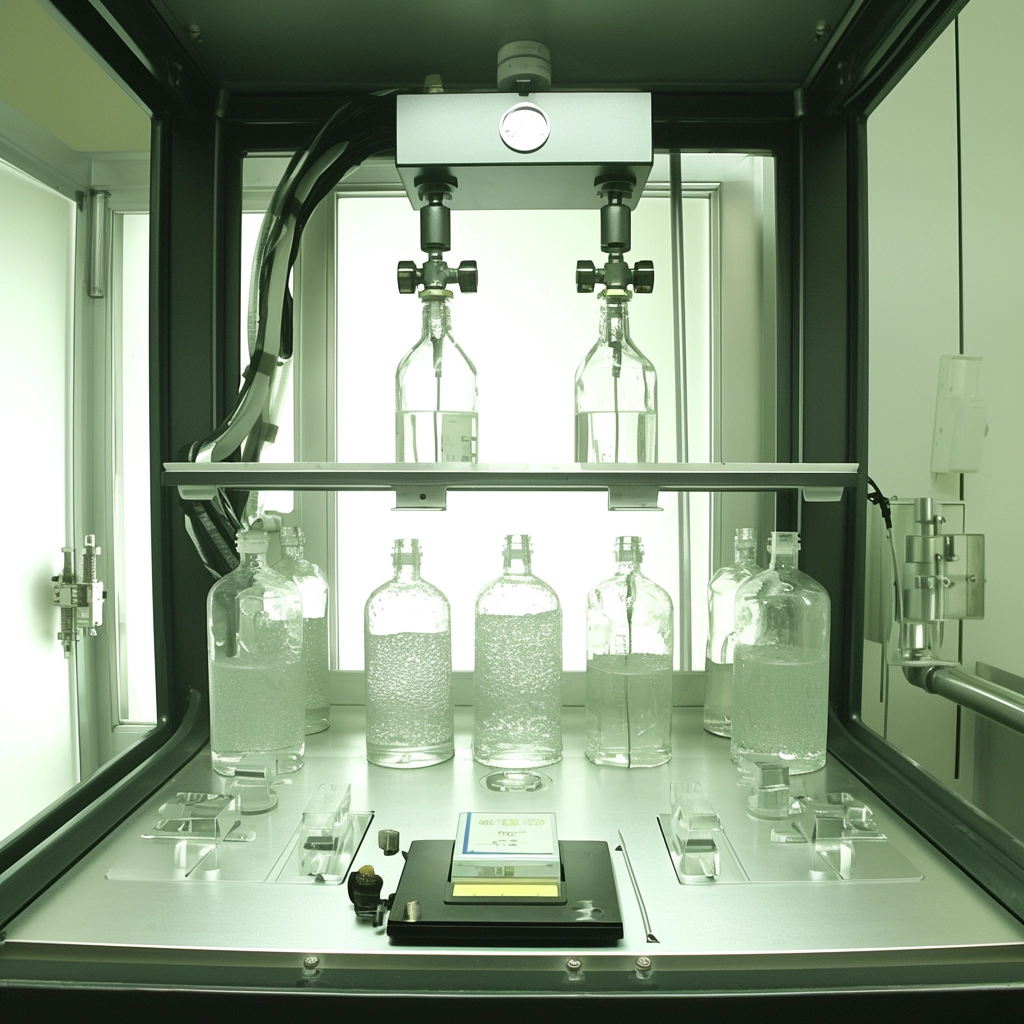

machine testing

Appearance inspection

- Dimension measurement: Use precision measuring tools such as calipers and micrometers to check whether the height, diameter, and mouth size of the glass bottle meet the design requirements. Ensuring the accuracy of the size is crucial for subsequent filling, sealing, and other links.

2.Surface inspection: Check whether there are bubbles, scratches, cracks, impurities, and other defects on the surface of the glass bottle by visual inspection or with the help of a magnifying glass. A smooth and flawless surface can not only enhance the aesthetics of the product, but also ensure the quality and safety of the product.

3.Shape inspection: Check whether the shape of the glass bottle is regular, and whether there are problems such as deformation and skewness. A good shape helps to improve the stability and packaging effect of the product.

Strength inspection

1.Pressure resistance test: Place the glass bottle under a certain pressure environment to test whether it can withstand the specified pressure without breaking. This is especially important for glass bottles that package liquids or gases, which can ensure that they will not be damaged by pressure changes during transportation and storage.

- 2.Impact resistance test: Use an impact tester to perform an impact test on the glass bottle to simulate the impact that the glass bottle may be subjected to during transportation and handling. Test whether the glass bottle can withstand a certain impact without breaking to ensure the safety of the product.

3.Thermal shock test: For glass bottles that need to withstand temperature changes, thermal shock test is performed. Quickly switch the glass bottle between high and low temperature environments to test whether it will break due to temperature changes. This can ensure that the glass bottle has good stability in different usage environments.

Sealing test

- 1.Bottle mouth sealing test: Install the bottle cap or seal on the glass bottle, and test whether the bottle mouth is sealed by applying a certain pressure or vacuum. Ensure that the product will not leak during storage and transportation.

- 2.Bottle bottom sealing test: For some special glass bottles, such as products that need to be inverted or placed on their sides, bottle bottom sealing test is performed. Test whether the sealing of the bottle bottom can meet the use requirements.

Manual inspection

I. Appearance inspection

Carefully observe the overall appearance of the glass bottle to check for obvious defects, such as bubbles, cracks, scratches, etc. These defects may affect the strength and aesthetics of the glass bottle.

Check whether the shape of the glass bottle is regular and whether it is deformed or twisted. Make sure that the size of the glass bottle meets the standard requirements, including height, diameter, bottle mouth size, etc.

Check the surface finish of the glass bottle for impurities, stains or spots. A clean and smooth surface helps to enhance the image of the product.

II. Sealing inspection

For glass bottles with sealing requirements, such as beverage bottles and medicine bottles, perform sealing inspections. You can observe whether there is liquid leakage or bubble generation by turning the bottle upside down or applying a certain amount of pressure.

Check whether the bottle cap or seal is installed firmly and whether it is loose or skewed. Ensure a good seal to prevent product leakage or external contamination.

III. Strength inspection

Gently tap the glass bottle to listen to whether its sound is crisp. A dull sound may indicate that the glass bottle has internal defects or is insufficient in strength.

Perform a moderate squeezing or bending test on the glass bottle to see if it can withstand a certain amount of external force without breaking. However, be careful to use moderate force to avoid excessive damage to the glass bottle.